LXN III. The Ultimate coil laser cutting machine.

In the words of our customers, this extraordinary machine is a real cashflow generator: material savings of over 20%, optimal management of long products and thin and delicate materials and also reduction to the minimum of manpower.

Discover with us the secrets of this Logical Revolution.

ACCURATE.

Like never before

The integrated vision system: our UNIQUE feature.

Precision processing of long or pre-punched products?

Using material right up to the edges? If you work with traditional lasers, they’re all huge problems.

Yes, they’re also the great advantage of the LXN III, thanks to a patented vision system that centers processing in relation to the edges and axis of the coil.

No other machine provides such precision and versatility.

Discover moreAccurate

Maximum precision thanks to the Dalcos vision patented system.

It works very simply: once the portion of the coil is fed, the vision system measures the position of the material and compares it to the theoretical position.

Then, it automatically applies any corrections by performing the roto-translation of the processing, if necessary, aligning It to the true position of the

material.

This simple tool allows:

- Processing of long pieces, even lengthier than the size of the machine bed (up to 14 meters) with very high precision

- Processing and production using 100% of the material, also using the edge of the coil as the side of the product

- Nesting pieces without restrictions or worrying about the length of the sheet: the CAD CAM program automatically adapts the products to the

working range of the machine (in this case, infinite length!)

- Making perfect joint cuts, even with multiple processing

- Laser re-processing pre-punched pieces (which is what allowed us to create the best combined coil-fed line on the market!)

This is one of the elements that make Dalcos’ “Coil To Laser” cutting system unique: a true Revolution on the coil-fed processing systems scene.

So: do you manufacture long products?

Contact us here and check how LXN laser cutting can provide the solution to your production problems!

New levels of EFFICIENCY.

Stop wasting material, especially today.

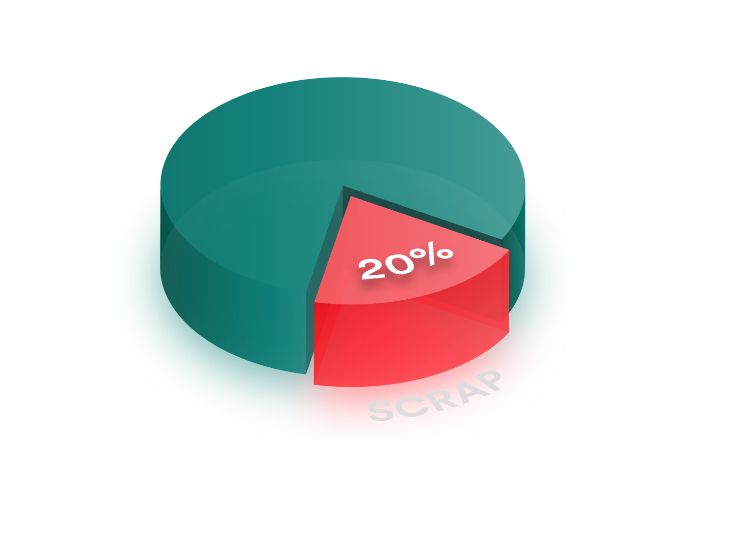

Did you know that traditional sheet metal laser cutting probably means you’re wasting more than 20% of your raw material?

If you’ve also been adversely Impacted by material cost increases in 2020 and 2021, you can acquire a strategic asset that will give you enormous advantages over your competition: thanks to a built-in vision system, the revolutionary LXN coil fed laser cutting system lets you process material right up to the edges, optimizing material use up to almost 100%.

Discover moreEfficiency

Traditional sheet-fed laser cutting produces huge amount of waste.

Traditional sheet-fed laser cutting is now so widespread that we almost don’t see its limitations.

The traditional system forces us to nest pieces on a sheet, which is a limited area: the rate of waste often reaches and exceeds 20% of the raw material.

It’s right in front of our eyes when we go into production, to the extent that we hardly notice it anymore and we almost consider it to be normal and

inevitable: crates of waste material, the “skeleton” from processing that needs to be managed and then disposed of.

Yet, all we need to do is analyze the rate of waste and the raw material purchases of our company in order to understand how much more profitable the

whole company would be if we were able to eliminate or even merely reduce that waste – for example, even and above all when expensive materials

such as copper and stainless steel are used!

It’s a waste of money and resources, which could instead be turned into cash flow available to your company.

The technology to drastically improve the use of material in laser cutting exists and it’s simple to use and implement.

Every detail RE-ENGINEERED.

We didn’t left anything to chance.

Our engineers have redesigned the LXN down to the smallest detail: the new solutions adopted range from the lighting of the vision system, which further increases its accuracy, to the support system that allows easy cleaning and replacement of the bars.

All patented so that these exclusive solutions represent your competitive advantage.

Discover moreDesign

Breathtaking new design for a revolutionary project.

Inspired by the shapes of supercars, the new design of the Dalcos LXN is itself something of a revolution: it reflects the production speed of the line and

the many innovations included in the new LXN, such as the patented extraction system and the new vision system, rendered even more precise and

reliable.

The latter two are part of many others included on this machine: a rapid replacement system of the fakirs, a special locking system that ensures maximum

safety and, of course, a repositioning and measurement system with roto-translation of the programs, already present on LXN lines of previous

generations.

To see the new Dalcos LXN III. in action, contact our specialists here or sign up for our dedicated Masterclasses!

LXN 1000

LXN 1000 is a compact system for coils ranging from 80 to 1000mm in width and work tables ranging from 1000 to 3000mm. Fully customizable with a de-coiler, straightener and feeder suited to your type of material and a complete range of unloading systems.

Discover moreLXN 1000

Fast, Powerful, User friendly: LXN III. 1000 is the Dalcos most versatile fiber laser.

Coil- and sheet- fed laser cutting system DALCOS LXN III. 1000 combines the well-known advantages of coil processing, such as automated operation

and raw material optimization, with the flexibility of fiber optic laser cutting and the possibility of machining sheets including special formats up to 12

meters long.

Operation is very simple: the cutting head moves along the X and Y axes while the sheet remains in position to ensure maximum cutting precision; the

patented DALCOS vision system guarantees precision and repeatability.

Elements making up the system are:

- 6000kg decoiler

- ERGO 1000 feeder with built-in straightener

- LXN 1000 fiber optic laser cutting system

- Fiber optic laser source from 1000W up to 4000W

- Chiller cooling system

- ALMACAM programming/nesting software for processing coils of the same width as the product (100% material used)

Features of the system:

- Working area 1000x1000mm and 1000x2500mm

- Machinable material: from 0.5 to 3mm gauge, up to 1000mm in width

- Source by IPG Photonics

LXN 1500

LXN 1500 is Dallan’s BestSeller system: with a built-in vision system, a conveyor belt with removable bars and an extraction system, every aspect of this machine has been carefully studied and subsequently patented: find out how to customize your system and get the most from your new LXN!

Discover moreLXN 1500

Advanced technical solutions: LXN 1500 fiber laser is the perfect fit for large formats.

The automatic laser cutting system from coils and sheets model DALCOS LXN 1500 has the most versatile setup. It processes with the maximum simplicity

strips up to 1550mm in width, and sheets up to 14 meters in length with a very compact layout.

The working range of 2500mm allows to perform extremely complex machining, with the precision guaranteed by the Dalcos vision system.

Elements making up the system are:

- 8000kg decoiler

- Dalcos feeder

- LXN 1500 fiber optic laser cutting system

- Fiber optic laser source from 1000W up to 4000W

- Chiller cooling system

- ALMACAM programming/nesting software for processing coils of the same width as the product (100% material used)

Features of the laser system:

- Working area 1500x2500mm

- Machinable material: from 0.5 to 3mm gauge, up to 1500mm in width

- Source by IPG Photonics

AUTOMATION.

Growing, without the

need to hire.

Employ people where you really need it, LXN does it all by itself.

How about simple system that allows unattended processing?

LXN is undoubtedly the solution! You can be sure of the quality of your products thanks to its vision system and coils allow you to load and process large quantities of raw material, while the pick and place unloading or stacking systems allow processing without the need for personnel directly dedicated to this machine, even with the lights off.

Discover moreAutomations

What about unloading pieces?

Every company has different needs: often pieces need to be stacked directly off the line (automatic picking and sorting) or perhaps entire sheets are

stacked with the parts nested and micro-jointed inside.

Other times, products are moved by rollers and conveyor belts directly to the folding area.

One of the advantages we have is that we can adapt the end-of-line to the best production logistics for the customer thanks to a complete range of

stacking systems (Cartesian, anthropomorphic, with removable roller conveyors) and handling systems that are made-to-measure based on your

company’s layout.

To find out more about all our stacking and handling solutions, and for a customized layout, contact our specialists here!

The SOFTWARE.

Time is money, don’t waste it

unnecessarily.

Automation at the highest level is not restricted to the workshop.

It also Involves having the right software to save thousands of hours a year of laser programming: find out how Dallan customers have achieved extraordinary results.

Discover moreSoftware

Program the machine in an automatic and parametric manner.

So: how do you program a machine like this?

If your pieces are repetitive, once you have created the program, you clearly just have to select and repeat it a certain number of times.

However, the market is evolving in a completely different direction. In industrial production, the aim Is to design products to adapt them to standardized

materials (where coil Is king), but production often requires the creation of parts from different families, with parametrically variable dimensions.

Normally, CAD drawings would need to be produced for each part, then nested each time in a sheet, creating a different machine program.

Coil-fed processing means there are two very interesting alternatives available.

The first is automatic nesting starting from pre-generated DXF files.

This is the solution adopted by CaptiveAire, for example, using a customized software that works as follows: the customer’s CAD software breaks down

the kit of panels that make up the product starting from numerical parameters (this is the customer’s CAD software). You drag all the DXF files that make

up an assembly kit using the LXN’s CAD CAM software: the program automatically positions them on a portion of the coil and the length of the portion

is adapted automatically!

The pieces that make up the kit are then cut and unloaded from the machine in the same panel: that way, the operator is sure to have all the necessary

components ready to be folded in order to make a specific hood with customized dimensions!

The second programming option is parametric programming: when products have common characteristics (front and back or holes), as in the case of

industrial door and door panels, you can automate the programming of the machine and the generation of job lists without even generating a DXF file:

the product parameters and references of the Master programs are passed along to the programming software and the work programs are automatically

generated together with the paths of the cutting head.

These two extraordinary programming systems can be used for different types of production: contact our specialists here to check which programming

system is best suited to your company!