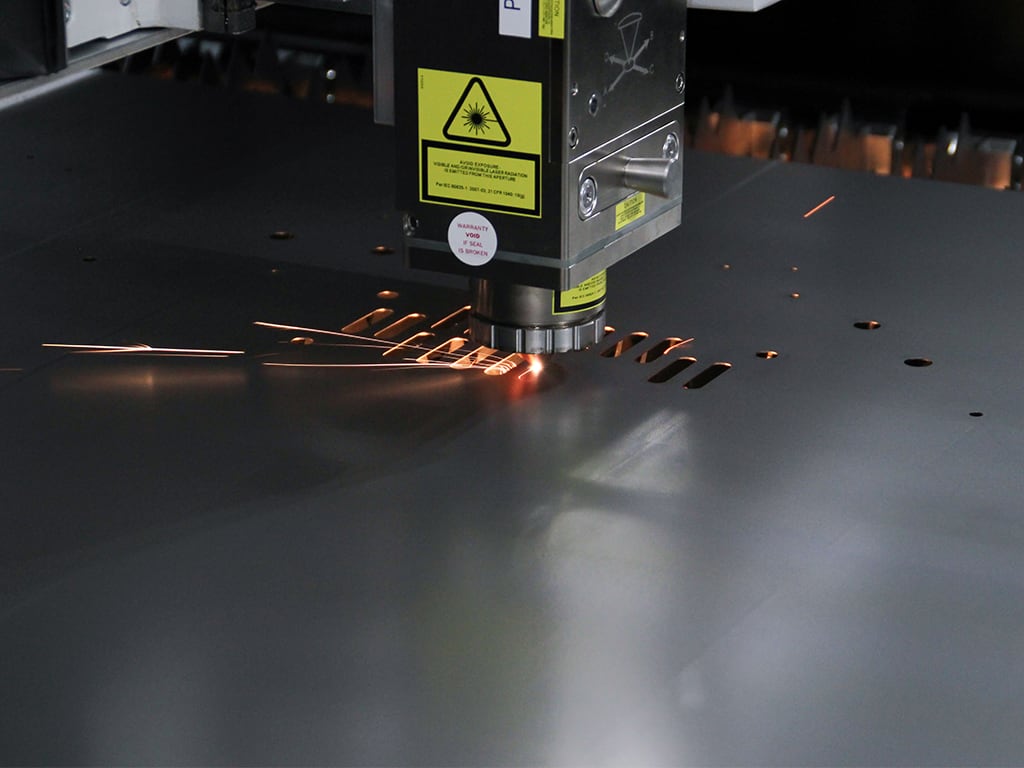

Simplicity meets the best laser cutting technology.

Laser cutting and saving up to 20% of raw material? Cutting long products without storing sheets in special formats on the premises?

Do you want to cut both sheets and coils?

The solution is simple and at hand: since 2013, Dalcos has been developing coil-fed laser cutting systems and that’s precisely why they allow

you to optimise the cutting surfaces!

Not only that: we have patented solutions, such as the vision system, which allow you to reposition the coil with extreme precision, processing

the entire surface right up to the edge. Come with us to discover how these extraordinary technologies work!

VERSATILITY.

The vision system allows you to work with the utmost simplicity on both single sheets and continuous coils; in doing so, the Dalcos LXN Vision is perfect for the most flexible production and for the automatic production of large batches.

Furthermore, Dalcos LXN Vision is the best processing system for long products, up to 14 metres in length.

EFFICIENCY AND MATERIAL SAVINGS.

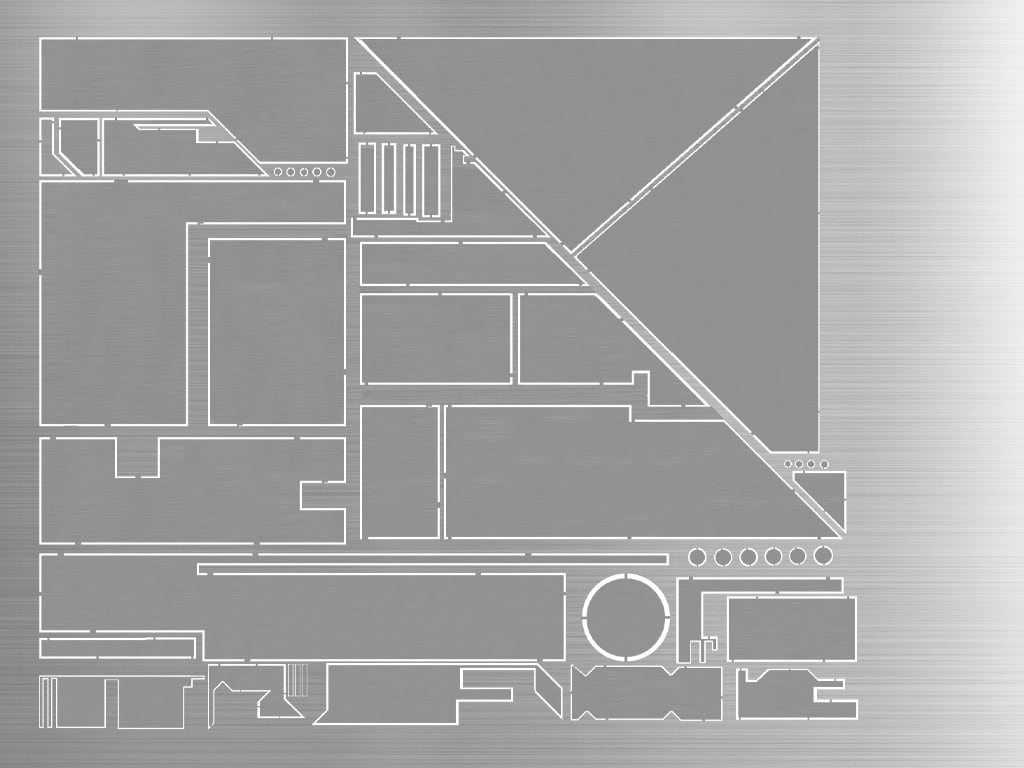

The vision system allows processing of material right up to the edge with up to100% utilisation and the elimination of the skeleton; moreover, the DALCOS LXN 1500 model has a passage measuring 1550mm, which allows the direct use of untrimmed coils without the need to guide the material laterally: the Dalcos vision system takes care of centring the processing at each step.

SPEED.

The automatic processing cycle allows continuous processing for up to 24 hours with a single coil: thanks to the speed of the fibre laser and the simultaneous loading and unloading of the work area, Dalcos LXN Vision achieves the utmost processing speed.

Furthermore, the 2000 and 2500mm long worktable allows the execution of complex products eith nesting at maximum speed and also very long products with the minimum number of positional adjustments.

LXN 1500.

Cutting-edge technical solutions:

LXN 1500 is the ideal Dalcos fibre laser

cutter for large formats.

The automatic coil-fed and sheet-fed laser cutting system mod. DALCOS LXN 1500, is by far the most versatile laser cutting system. It processes coils up to 1550mm in width and sheets up to 14 metres in length with the utmost simplicity, even in a very compact layout.

The 3000mm working area allows the execution of extremely complex processing, with the precision guaranteed by the Dalcos vision system.

Find out moreLXN 1500

Cutting-edge technical solutions: LXN 1500 is the ideal Dalcos fibre laser cutter for large formats.

The automatic coil-fed and sheet-fed laser cutting system mod. DALCOS LXN 1500, is by far the most versatile laser cutting system. It processes coils up

to 1550mm in width and sheets up to 14 metres in length with the utmost simplicity, even in a very compact layout.

The 3000mm working area allows the execution of extremely complex processing, with the precision guaranteed by the Dalcos vision system.

The elements that make up the system are:

- 8000kg decoiler

- ERGO 1500 feeder

- LXN 1500 fibre laser cutting system

- 1000W and 2000W fibre laser source – 3000W and 4000W upon request (produced by IPG Photonics)

- Chiller cooling system

- SIGMANEST programming software for the execution of nesting operations and using coils with a width equal to the product (material yield 100%)

System features:

- Working area 1550x3000mm

- Workable material: from coils 0.5-3mm in thickness, 1550mm in width – from sheets up to 4mm in thickness

- Source produced by IPG Photonics

LXN 1000.

Fast, powerful, easy to use: the LXN

1000 is Dalcos’ most versatile fibre

laser.

Coil-fed and sheet-fed laser cutting mod. DALCOS LXN 1000 combines the acknowledged advantages of coil-fed processing, such as automatic operation and optimisation of raw material, with the flexibility of fibre laser cutting processing and the option of sheet-fed processing managing special formats up to 12 metres in length.

Operation is extremely simple: the cutting head works in X and Y axes, while the sheet remains in position to ensure maximum execution precision; the Dalcos® patented vision system guarantees precision and repeatability.

Find out moreLXN 1000

Fast, powerful, easy to use: the LXN 1000 is Dalcos most versatile fibre laser.

Coil-fed and sheet-fed laser cutting mod. DALCOS LXN 1000 combines the acknowledged advantages of coil-fed processing, such as automatic

operation and optimisation of raw material, with the flexibility of fibre laser cutting processing and the option of sheet-fed processing managing special

formats up to 12 metres in length.

Operation is extremely simple: the cutting head works in X and Y axes, while the sheet remains in position to ensure maximum execution precision; the

Dalcos® patented vision system guarantees precision and repeatability.

The elements that make up the system are:

- 6000kg decoiler

- Feeder with built-in ERGO 1000straightener

- LXN 1000 fibre laser cutting system

- 1000W and 2000W Fiber laser source – 3000W and 4000W upon request (produced by IPG Photonics)

- Chiller cooling system

- ALMACAM programming software for the execution of nesting operations and using coils with a width equal to the product (material yield 100%)

System features:

- Working area 1000x1000mm and 1000x2500mm

- Machinable material: from 0.5 to 3mm in thickness, up to 1000mm in width

- Source produced by IPG Photonics